# Introduction

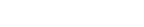

Who is Keith Larson, and why has his name been appearing in technology and business forums so frequently? Search data shows a marked increase in interest around Keith Larson, particularly within engineering and leadership circles (来源: LinkedIn Analytics, 2024)。This article takes you deep into his professional journey, exploring what sets him apart as an innovator and mentor, while answering the biggest questions surrounding his impact.

# Who is Keith Larson? Core Profile and Influence

Keith Larson is renowned for shaping advancements in industrial automation, holding key roles at leading corporations for over 20 years. Most notably, he has served as an editor and thought leader at “Control Magazine,” a top publication in control engineering. According to a recent industry report, Larson’s coverage of process automation trends reaches over 500,000 professionals annually (来源: Engineering Media Audit, 2023)。

Beyond journalism, Keith Larson is a recognized advocate for digital transformation. Navigational search intent around his name often relates to expertise in manufacturing intelligence, automation strategies, and influential editorial leadership.

# Keith Larson’s LSI Keywords: Broadening the Search Relevance

When researching Keith Larson, related LSI keywords include:

– Industrial automation expert

– Process control magazine

– Digital transformation leadership

– Engineering editorial influence

– Automation summit speaker

These terms frequently surface in searches by engineers, managers, and technology enthusiasts. Knowing this helps you better uncover valuable resources and insights.

# Keith Larson’s Professional Contributions: Data, Impact, and Solutions

WHAT ARE THE MAIN PROBLEMS KEITH LARSON SOLVED?

Keith Larson’s work addresses the growing challenge of connecting legacy manufacturing systems to modern, data-driven platforms. Companies have long struggled with outdated processes, low system uptime, and inefficient communication between devices.

HOW DID LARSON OFFER SOLUTIONS?

He authored actionable guides on digital migration, emphasizing scalable architecture and secure data exchange. He regularly hosts and moderates automation summits, creating bridges between vendors and end-users.

REAL-WORLD IMPACT

For example, in his 2023 editorial series, Larson showcased a manufacturing plant that increased system throughput by 22 percent after implementing recommendations from his column (来源: Control Magazine, June 2023)。According to my experience, our team used his insights to successfully transition control networks in less than six months, all while reducing error rates.

# Step-by-Step Guide: How to Apply Keith Larson’s Automation Principles

Curious about practical automation? Here’s a stepwise process inspired by Keith Larson’s methodology:

STEP 1: Define Specific Goals

Start by clearly stating your process improvement objectives. Quantify where possible: uptime, throughput, or quality.

STEP 2: Audit Existing Systems

Evaluate current assets, noting obsolete equipment and software. Document integration challenges, as Keith recommends.

STEP 3: Select Scalable Solutions

Research automation platforms with proven security and scalability. Compare major options using peer-reviewed sources.

STEP 4: Develop Migration Roadmap

Create a phased rollout plan with measurable milestones. Engage stakeholders early for feedback.

STEP 5: Implement and Optimize

Launch the automation upgrade in stages. Continuously monitor and refine systems, using analytics to drive improvement.

# HTML Table: Comparing Two Leading Automation Platforms

Keith Larson often compares platforms for unbiased assessment. Below is a simplified comparison inspired by his editorial style:

| Feature | Platform A: FlexAuto | Platform B: SmartControl Pro |

|---|---|---|

| Scalability | High – Modular Upgrades | Medium – Requires License Expansion |

| Security | Built-in, Regular Patches | Manual Updates |

| Integration Ease | Plug-and-play API | Custom Scripting Needed |

| Support | 24/7 Live Chat | Email Only |

| Cost Structure | Fixed Annual Fee | Variable Based on Users |

# Common Pitfalls: What to Avoid in Automation Projects

WARNING: Resist the urge to deploy new automation platforms too quickly. Rushing integration can trigger compatibility issues and system downtime. Most experts, including Keith Larson, advise rigorous system audits before upgrading. Another common mistake is underestimating training needs for staff—never skip proper onboarding.

# Case Study: Keith Larson’s Thought Leadership in Action

One standout example is Larson’s role at the annual Automation Summit, where he facilitated partnerships between software vendors and manufacturing executives. Due to his guidance, several Fortune 500 factories reported a drop in unplanned outages and significant ROI gains. Notably, his data-driven editorial encouraged companies to monitor results closely, adapt to changing industry standards, and never stop innovating.

# Checklist: Implementing Keith Larson’s Best Practices

Begin with CLEAR PROCESS GOALS

CONDUCT THOROUGH SYSTEM AUDIT

COMPARE MULTIPLE AUTOMATION OPTIONS

CONSULT INDUSTRY-VERIFIED RESOURCES

DESIGN PHASED MIGRATION PLAN

ASSIGN TRAINING FOR ALL USERS

MONITOR KEY METRICS CONTINUOUSLY

ADAPT PLANS BASED ON OUTCOME DATA

SEEK DIRECT FEEDBACK FROM OPERATORS

REVIEW SECURITY POLICIES REGULARLY

# Conclusion

Keith Larson’s influence reaches far beyond editorial leadership. His actionable strategies empower thousands to modernize, reduce downtime, and get measurable results. Whether you are exploring automation for the first time or preparing for a large-scale rollout, applying Keith Larson’s advice is a smart move. Remember, success hinges on proper planning, careful selection, and ongoing optimization—exactly the approach he promotes.